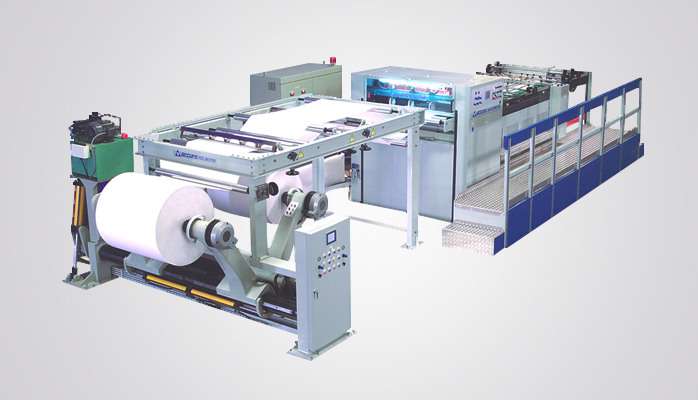

Slitting machine

Slitter blade slitting cardboard tail deflection:

1. The paper feeding positioning baffle of the slitter blade is improperly adjusted; 2. One section of the slitter blade is too blunt, which is different from the linear speed of other knives; 3. The paper guide wheel of the slitter blade is improperly adjusted; 4. The paper feeding of the slitter blade is improper.

Slitter blades produce burrs:

1. The blade of the slitter is blunt and should be polished; 2. The blade of the slitter overlaps with the groove too shallowly; 3. The paper edge and the paper wool are drawn into the groove of the slitter blade, which should be cleaned thoroughly before starting the machine; 4. The gap between the grooves of the slitter blade is too large, which should be no more than 2.5mm in general.

The indentation line of cutter blade is easy to crack:

1. The base paper is inferior; 2. The line pressing is too deep.

The indentation line of cutter blade is not straight:

1. The slitter blade is too shallow and the broken line is uneven, which affects the appearance of the box; 2. The paper feeding of the slitter blade is skewed; 3. The upper and lower pressing wheels of the slitter slitter blade of the slitter rewinder are not aligned.

The cutting edge of cutter blade is not vertical:

1. The angle of the blade holder of the slitter is not right; 2. The blade of the slitter is not in the center of the groove; 3. The blade of the slitter is eccentric.