The history of slitter development is briefly introduced by Slitter manufacturer.

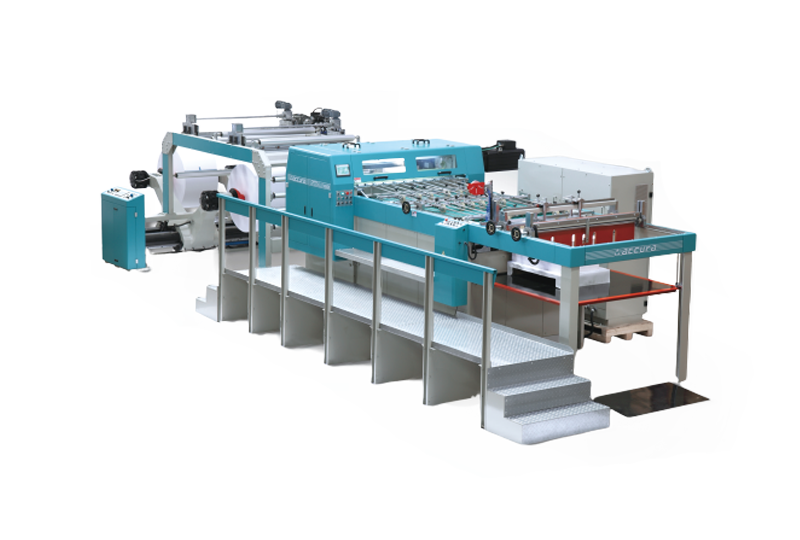

The cutting machine is a pre press and post press equipment that cuts a large roll of paper, film, non-woven fabric, aluminum foil, mica tape and other thin materials into small rolls of different width, commonly used in paper-making machinery and printing packaging machinery.

In the past, the speed of magnetic powder clutch of slitter can not be high, because it is easy to cause high-speed friction of magnetic powder during operation, generate high temperature, shorten its service life, and in serious cases, it will block the operation of the machine, which will bring serious consequences to production.

Seriously affected the production efficiency. At present, double frequency conversion motor control is used to make the magnetic powder friction at a certain value through frequency conversion motor control when the diameter of the winding material becomes larger. Without high temperature.

The traditional control scheme of the slitter is to use a large motor to drive the winding shaft. A magnetic powder clutch is added to the winding shaft. The resistance produced by the magnetic powder clutch is controlled by adjusting the current of the magnetic powder clutch to control the tension of the material surface. Magnetic powder clutch and brake is a kind of special automatic actuator. It transfers torque through magnetic powder filled in the working gap. Changing the magnetic current can change the magnetic state of magnetic powder, and then adjust the transmitted torque. It can be used for stepless speed regulation from zero to synchronous speed, and it is suitable for high-speed section fine-tuning and small and medium power speed regulation system. It is also used to adjust the torque by adjusting the current to ensure that the tension in the winding process remains constant.

The slitter is developing from single motor control to double motor and three motor control, which is more stable and efficient when the machine speed is faster.

The main feature of the slitter is that as a resistance device, the magnetic powder clutch outputs a DC voltage through system control to control the resistance produced by the magnetic powder clutch. The main advantage is that it is a passive device, which can control small tension.

Disadvantages: the speed can not be high, high-speed operation is easy to cause high-speed friction of magnetic powder, resulting in high temperature, resulting in heating of magnetic powder clutch and shortening its service life. A device used to cut a certain width of coiled material longitudinally and cut several narrow coils. After it is installed in calender, extruder, glue applicator and other unit devices, it can complete continuous slitting, often with winding device. The blade cutter can use flat blade cutter and round blade cutter.

Paper processing machinery Slitter series products: paper Slitter, small paper Slitter, web Slitter, high-speed Slitter, etc

Metal cutting machine: steel strip cutting machine, copper plate cutting machine, aluminum plate cutting machine, stainless steel cutting machine, sheet cutting machine, etc.