Three development directions of automatic Slitter industry.

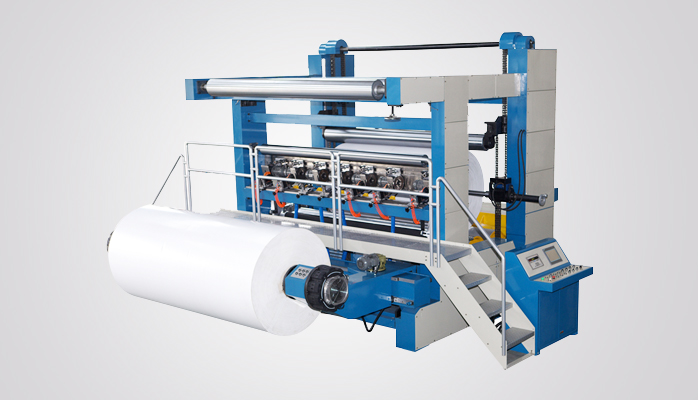

The development of automation machinery is now the focus of our traditional industry. The innovation, structure reconstruction, system improvement and process improvement of the extruder are the important reasons for the rapid development of modern mechanical equipment. The slitter is a kind of mechanical equipment which cuts the wide paper, mica tape or film into several narrow materials. It is commonly used in papermaking machinery, wire and cable mica tape and printing and packaging machinery.

Expert analysis, the product improvement and innovation technology of automatic Slitter will bring certain development impetus to the automatic machinery industry. The slitter is developing from single motor control to double motor and three motor control, which is more stable and efficient when the machine speed is faster. The main feature of the slitter is that as a resistance device, the magnetic powder clutch outputs a DC voltage through system control to control the resistance produced by the magnetic powder clutch. The main advantage is that it is a passive device, which can control small tension. Working principle of automatic Slitter:

1. The paper Slitter shall cut the whole roll or the whole sheet of raw materials with fixed length, such as plastic packaging materials, packaging cartons, steel plates, films, leather, wood chips, etc., which shall be controlled by fixed length slitting.

2. The cutting length can be set continuously. If there is any error in the actual cutting length, it is easy to calibrate by setting parameters.

3. The slitting control of the paper Slitter is divided into static and dynamic slitting: stop the machine accurately when the set length reaches, then static slitting processing, restart the operation after slitting; when the set length reaches, send the slitting signal without stopping, and the slitter will conduct dynamic slitting processing in the process of material movement.

In the future development and construction, the slitter will mainly develop and improve in three directions:

1. Frame structure: no matter once or twice or thrice slitting, domestic Slitter manufacturers should devote themselves to research on the frame structure, design a more reasonable Slitter practically from the perspective of slitter manufacturers, get rid of the plagiarism phenomenon of the slitter produced by them, research and design a personalized Slitter, so as to make the slitter of different materials more detailed in structure In the next round of competition in the international market, we will provide favorable weapons for the film making enterprises and find a blue ocean for our own enterprises.

2. Automation control part: at present, the automation level of domestic slitter is still at the middle and lower level. Although the application of domestic control original devices has been very popular and the price is relatively low, the domestic Slitter manufacturers are far behind the level of foreign developed countries in the depth of use, especially in the control system, the structure of slitter and the materials to be cut In this aspect, the majority of domestic slitters still stay on the thick lines, and have not yet understood the tightness and rationality of the control system of the slitter. The domestic Slitter manufacturers should start from the above several directions to find out a way that not only conforms to the slitter control and slitting principle, but also can use the functions provided by the hardware well.

3. Manufacturing: This is a common problem faced by China's manufacturing industry. In addition to reasonable design, any mechanical equipment also requires precision in manufacturing, which China's manufacturing industry lacks. In addition, the manufacturing process is also a weak link. Apart from some general machine tools, the equipment for manufacturing Slitter also needs some special equipment for manufacturing slitter For example, dynamic balancing machine, water cutting machine, etc., due to the high manufacturing accuracy requirements of the slitter, some equipment needs to use CNC machine tools to process parts, especially it is necessary to popularize the use of machining centers, so that the processing accuracy of the equipment manufactured by the slitter can be fundamentally guaranteed.

Only in the future, the traditional industry will continue to innovate and improve, or even be reborn with the progress of Internet technology, can it not be eliminated by the times, move towards a better market, and occupy a certain industry opportunity in the future of competitive incentive.